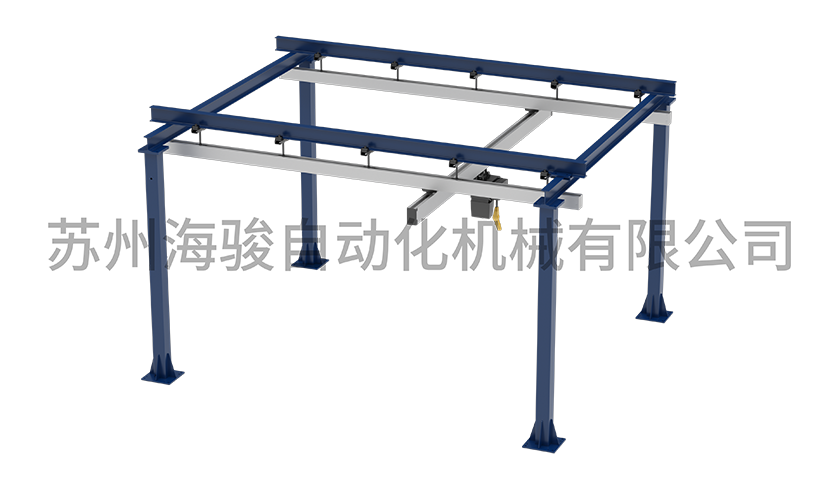

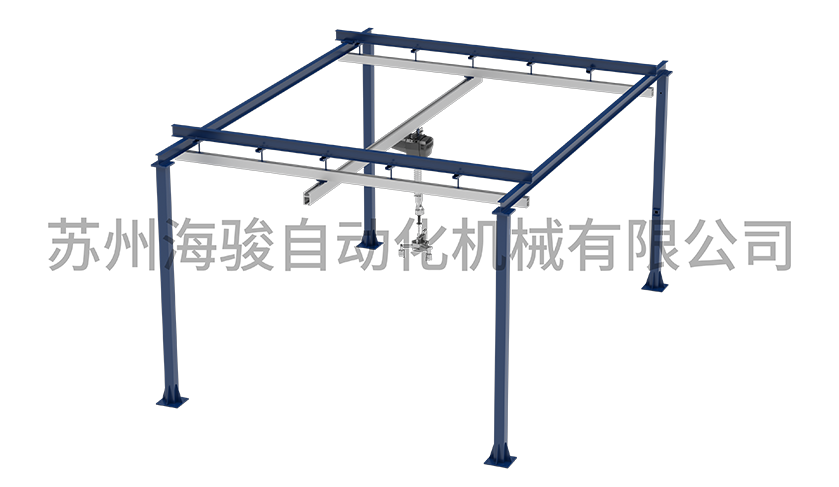

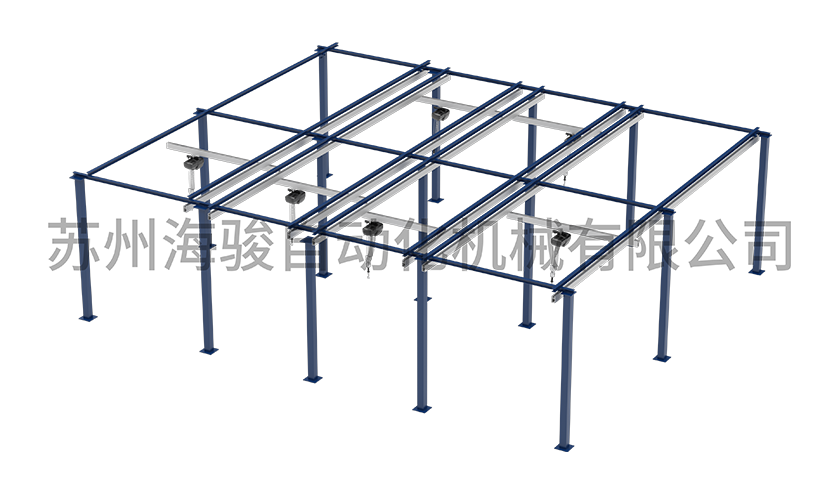

Truss Manipulator

subcategory:Truss Manipulator

Truss manipulators, also known as KBK rail systems, are composed of suspension devices, rails, turnouts, traveling trolleys, electric hoists, mobile power supply devices (slide wires), and control devices. Since this product only needs to be simply suspended on the steel structure of the workshop or gantry steel structure, and the aerial direct transportation of materials can be realized through lifting equipment, it is widely used in the material transportation links of various industries.

| Equipment Model | SZHJ-DZYD-C30 | SZHJ-DZYD-C50 | SZHJ-DZYD-C100 | SZHJ-DZYD-C200 | SZHJ-DZYD-C300 | SZHJ-DZYD-C500 |

| Main Model | HJZL-114/133 | HJZL-133 | HJZL-133/158 | HJZL-158/181 | HJZL-181/272 | HJZL-272 |

| Rated Load G | 30KG | 50KG | 100KG | 200KG | 300KG | 500KG |

| Swing Radius R1 | 2500mm | 2500mm | 2500mm | 2500mm | 2500mm | 2500mm |

| Lifting Stroke H | 1500mm | 1500mm | 1500mm | 1500mm | 1500mm | 1500mm |

| Maximum Lifting Height H1 | 2000mm | 2000mm | 2000mm | 2000mm | 2000mm | 2000mm |

| Lowest Point H2 | H1H | H1-H | H1-H | H1-H | H1-+H | H1-H |

| Base Height H4 | 200mm | 300mm | 370mm | Customized Design | Customized Design | Customized Design |

| Air Source Pressure P | 0.5Moa or above | 0.5Moa or above | 0.5Moa or above | 0.5Moa or above | 0.5Moa or above | 0.5Moa or above |

| Equipment Weight | 190KG | 370KG | 450KG | 510KG | Customized | Customized |

Truss manipulators, also known as KBK rail systems, are composed of suspension devices, rails, turnouts, traveling trolleys, electric hoists, mobile power supply devices (slide wires), and control devices. Since this product only needs to be simply suspended on the steel structure of the workshop or gantry steel structure, and the aerial direct transportation of materials can be realized through lifting equipment, it is widely used in the material transportation links of various industries.

Lifting Capacity Range: 25KG~2000KG:Including single-rail systems, LD single-girder, LS double-girder, LSS telescopic girder, and LM stacker types, with extremely wide applications. Key features are summarized below:

High Reliability and Stability:The KBK rail system consists entirely of standardized modular components, ensuring exceptional reliability. Maintenance, repairs, and part replacements are convenient, guaranteeing stable system performance.

Strong Adaptability:Flexible design and installation tailored to factory workstations. It can be configured for point-to-point transport or high-precision, multi-point automated conveying lines with variable cycles. Suitable for new facilities or system upgrades/extensions.

Easy Installation and Cost Efficiency:Simple setup and commissioning—modules and standard components require only bolted connections. Saves factory space and reduces operational costs. Systems can be manually operated or automated/semi-automated for efficient performance.

No. 269, Feng Road, Xukou Town, Wuzhong District, Suzhou

No. 269, Feng Road, Xukou Town, Wuzhong District, Suzhou 0512-66510322

0512-66510322 0512-66510623

0512-66510623 15306205950 (WeChat same)

15306205950 (WeChat same) szhaijun06@163.com

szhaijun06@163.com