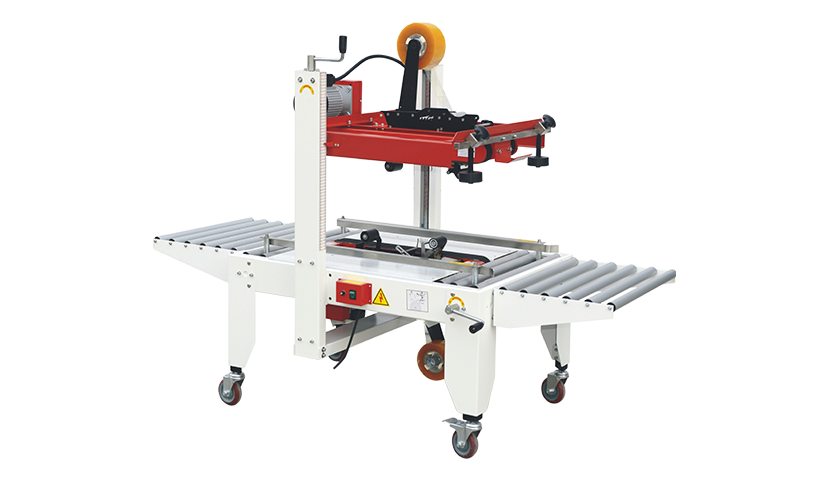

Strapping Machine

subcategory:Strapping Machine

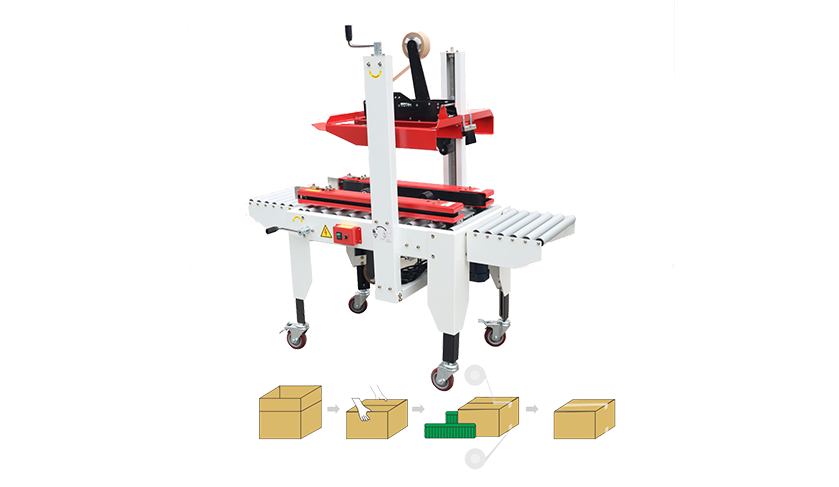

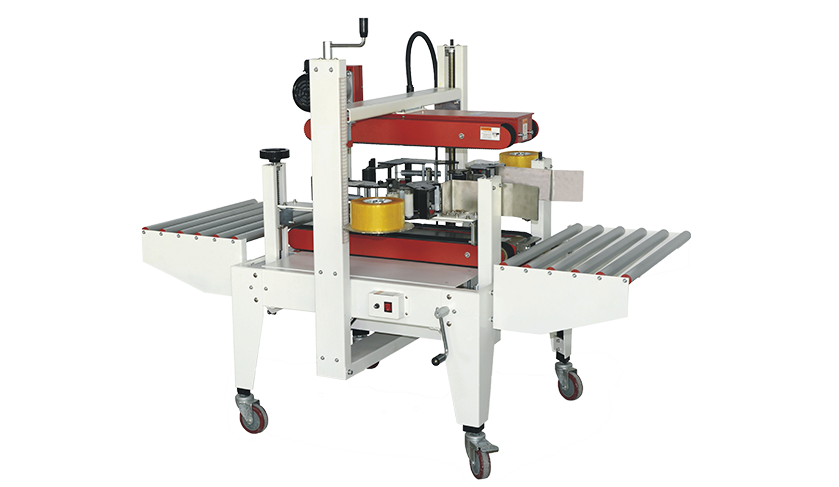

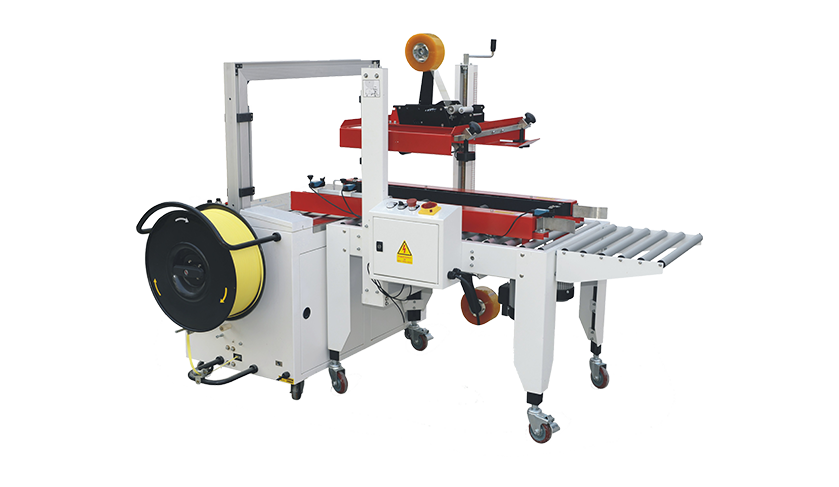

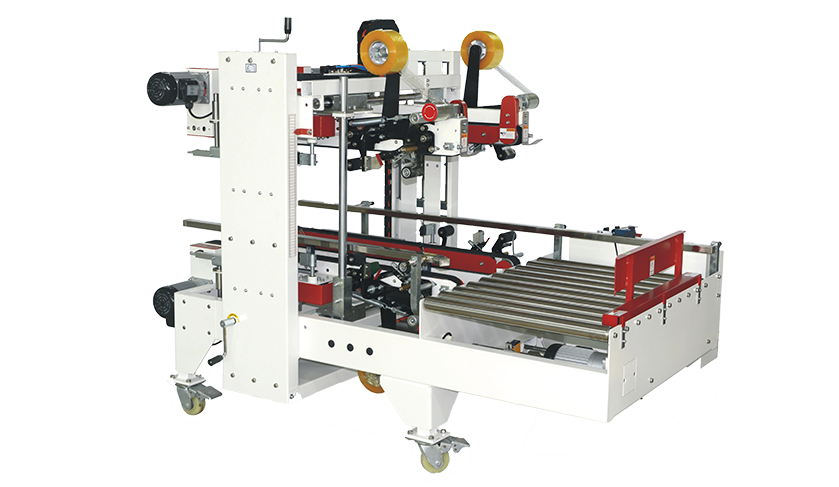

A strapping machine is an automated device that secures, reinforces, or seals products or packages by binding them with straps. It is widely used in logistics, food, pharmaceuticals, electronics, and other industries. Its core mechanism involves motor-driven strap tensioning followed by heat sealing (or metal clip fastening) to complete the packaging process.

A strapping machine is an automated device that secures, reinforces, or seals products or packages by binding them with straps. It is widely used in logistics, food, pharmaceuticals, electronics, and other industries. Its core mechanism involves motor-driven strap tensioning followed by heat sealing (or metal clip fastening) to complete the packaging process.

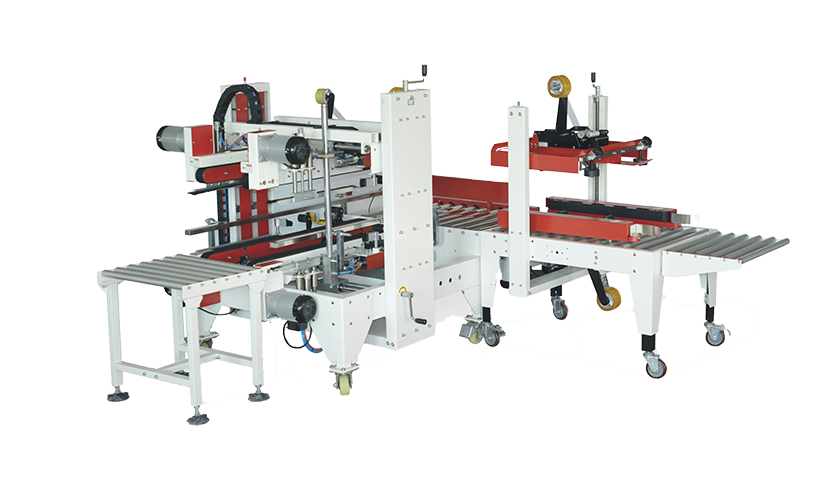

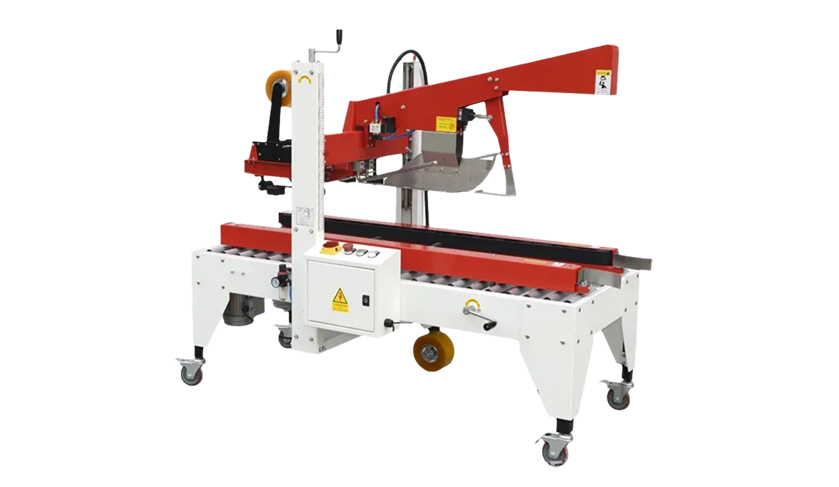

By functionality, strapping machines fall into two main categories: Semi-automatic (requiring manual strap placement, with the machine handling tensioning and sealing) and Fully automatic (automating feed, strapping, and cutting for higher efficiency). Based on strap materials, they include plastic (PP/PET) strapping machines and steel strap machines, catering to varying weight and strength requirements.

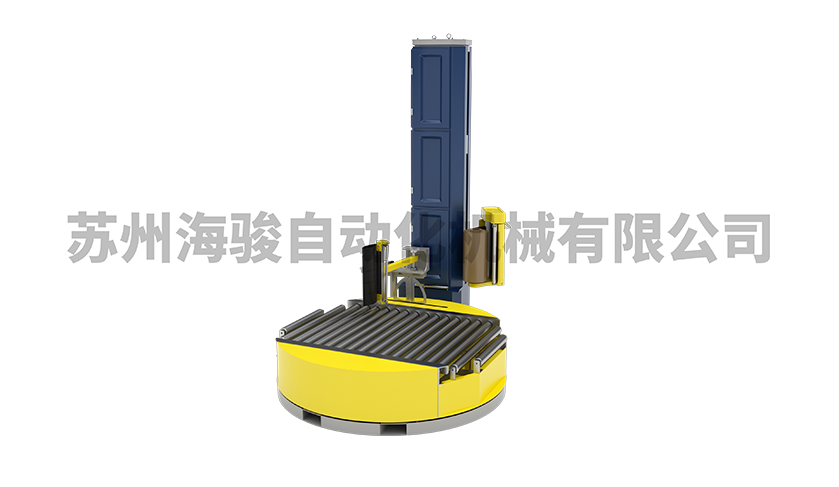

Advantages include ease of operation, secure bundling, and improved packaging efficiency, reducing product damage or spillage during transit while lowering labor costs. Common applications include carton sealing, timber bundling, and pallet stabilization. With industrial automation advancements, high-end models now integrate smart sensors, self-diagnosis, and remote monitoring, enhancing reliability and adaptability. These machines have become indispensable in modern supply chain packaging.

No. 269, Feng Road, Xukou Town, Wuzhong District, Suzhou

No. 269, Feng Road, Xukou Town, Wuzhong District, Suzhou 0512-66510322

0512-66510322 0512-66510623

0512-66510623 15306205950 (WeChat same)

15306205950 (WeChat same) szhaijun06@163.com

szhaijun06@163.com